Bottle filling lines – more than 1300 bottles per hour

Bottle filling lines – Powerfull machines to filling drinks into bottles

with production capacity more than 1300 bottles per hour

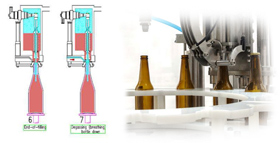

We offer bottle rinsing, filling, capping, labelling and handling machines (bottle filling lines) with production capacity more than 1300 bottles per hour. The lines are usually assembled from more blocks. Customer can choose the bottle filling line from more variants. The assembling blocks includes roller conveyors, bottle loaders and bottle collectors, packing machines and other equipment for the transport and handling of bottles. The level of automation and manual labor relationship with bottles depends on the financial possibilities of the customer and the space available in the brewery.

We offer bottle rinsing, filling, capping, labelling and handling machines (bottle filling lines) with production capacity more than 1300 bottles per hour. The lines are usually assembled from more blocks. Customer can choose the bottle filling line from more variants. The assembling blocks includes roller conveyors, bottle loaders and bottle collectors, packing machines and other equipment for the transport and handling of bottles. The level of automation and manual labor relationship with bottles depends on the financial possibilities of the customer and the space available in the brewery.

We offer these lines for filling of beer / cider into bottles :

- BCFL-MB1200 : Automatic counter pressure filling line for 1200 bottles or cans per hour

The automatic bottle and cans filling line BCFL-MB1200 is fully equipped filling technology with the production capacity up to 1200 bottles or cans (0,33L) per hour. It consists of these components and blocks : Automatic monoblock machine for rinsing, filling and closing the aluminium cans Set of parts for the rinsing, filling and capping the glass bottles in the main automatic monoblock - the set changes a functionality od the main monoblock machine to use it for operations with glass bottles. Special CIP bottle for full cleaning and sanitizing the machine in closed circuit. High temperature washing kit for the… Read more »

The automatic bottle and cans filling line BCFL-MB1200 is fully equipped filling technology with the production capacity up to 1200 bottles or cans (0,33L) per hour. It consists of these components and blocks : Automatic monoblock machine for rinsing, filling and closing the aluminium cans Set of parts for the rinsing, filling and capping the glass bottles in the main automatic monoblock - the set changes a functionality od the main monoblock machine to use it for operations with glass bottles. Special CIP bottle for full cleaning and sanitizing the machine in closed circuit. High temperature washing kit for the… Read more » - BFL-MB1200 : Automatic counter pressure filling line for 1200 bottles/hour

The automatic bottle filling line BFL-MB1200 is fully equipped filling technology with the production capacity up to 1200 bottles (0,33L) per hour. It consists of these components and blocks : Automatic monoblock machine for rinsing, filling and closing the glass bottles. Special CIP bottle for full cleaning and sanitizing the machine in closed circuit. High temperature washing kit for the hot internal cleaning of the machine at 85 ⁰C using a caustic solution. Linear labelling unit for application of paper labels on the bottles. Photocell to avoid bottle jam out in the labelling unit. Coder integrated into the labelling unit… Read more »

The automatic bottle filling line BFL-MB1200 is fully equipped filling technology with the production capacity up to 1200 bottles (0,33L) per hour. It consists of these components and blocks : Automatic monoblock machine for rinsing, filling and closing the glass bottles. Special CIP bottle for full cleaning and sanitizing the machine in closed circuit. High temperature washing kit for the hot internal cleaning of the machine at 85 ⁰C using a caustic solution. Linear labelling unit for application of paper labels on the bottles. Photocell to avoid bottle jam out in the labelling unit. Coder integrated into the labelling unit… Read more » - BCFL-MB1500TP : Automatic counter pressure filling line for 1500 bottles or cans per hour with a tunnel pasteurizer

The automatic bottle and cans filling line BCFL-MB1500TP is fully equipped filling technology with the production capacity up to 1500 bottles or cans (0,33L) per hour, with a tunnel pasteurizer. It consists of these components and blocks : Automatic monoblock machine for rinsing, filling and closing the aluminium cans Set of parts for the rinsing, filling and capping the glass bottles in the main automatic monoblock - the set changes a functionality od the main monoblock machine to use it for operations with glass bottles. Special CIP bottle for full cleaning and sanitizing the machine in closed circuit. High temperature… Read more »

The automatic bottle and cans filling line BCFL-MB1500TP is fully equipped filling technology with the production capacity up to 1500 bottles or cans (0,33L) per hour, with a tunnel pasteurizer. It consists of these components and blocks : Automatic monoblock machine for rinsing, filling and closing the aluminium cans Set of parts for the rinsing, filling and capping the glass bottles in the main automatic monoblock - the set changes a functionality od the main monoblock machine to use it for operations with glass bottles. Special CIP bottle for full cleaning and sanitizing the machine in closed circuit. High temperature… Read more » - BFL-MB2000TP : Automatic counter pressure filling line for 2000 bottles per hour with a tunnel pasteurizer

The automatic bottle filling line BFL-MB2000TP is fully equipped filling technology with the production capacity up to 2000 bottles (0,33L) per hour, with a tunnel pasteurizer. It consists of these components and blocks : Automatic monoblock machine for rinsing, filling and capping the glass bottles. Set of parts for the rinsing, filling and capping the glass bottles in the main automatic monoblock - the set changes a functionality od the main monoblock machine to use it for operations with glass bottles. Special CIP bottle for full cleaning and sanitizing the machine in closed circuit. High temperature washing kit for the… Read more »

The automatic bottle filling line BFL-MB2000TP is fully equipped filling technology with the production capacity up to 2000 bottles (0,33L) per hour, with a tunnel pasteurizer. It consists of these components and blocks : Automatic monoblock machine for rinsing, filling and capping the glass bottles. Set of parts for the rinsing, filling and capping the glass bottles in the main automatic monoblock - the set changes a functionality od the main monoblock machine to use it for operations with glass bottles. Special CIP bottle for full cleaning and sanitizing the machine in closed circuit. High temperature washing kit for the… Read more » - BCFL-3000IC : Automatic hybrid bottle/can filling line – capacity up to 3000 bottles or cans per hour

The automatic bottle and can filling line BCFL-3000IC is fully equipped filling technology with the operation capacity up to 3000 glass bottles or aluminium cans per hour (... this capacity is valid for 0.33L glass bottles or aluminium cans). Operation capacity: – Up to 2400 pcs of the 0.5 lt bottles or cans per hour – Up to 3000 pcs of the 0.3 lt bottles or cans per hour Our innovative beverage counter-pressure bottle/can filling line BCFL-3000IC includes the monoblock unit HYBRID 12-12-1SC EPV (Monoblock which includes the rinsing unit, the counterpressure filling unit, the crown capping unit and the… Read more »

The automatic bottle and can filling line BCFL-3000IC is fully equipped filling technology with the operation capacity up to 3000 glass bottles or aluminium cans per hour (... this capacity is valid for 0.33L glass bottles or aluminium cans). Operation capacity: – Up to 2400 pcs of the 0.5 lt bottles or cans per hour – Up to 3000 pcs of the 0.3 lt bottles or cans per hour Our innovative beverage counter-pressure bottle/can filling line BCFL-3000IC includes the monoblock unit HYBRID 12-12-1SC EPV (Monoblock which includes the rinsing unit, the counterpressure filling unit, the crown capping unit and the… Read more » - BFA-MB611 : Automatic counterpressure filling and capping machine for glass bottles and aluminium cans (up to 850 bph)

Compact fully automatic counterpressure filling and capping machine with two integrated units : fully automatic isobaric filling unit for glass bottles and aluminium cans - six electronic valves fully automatic pneumatic capping unit for the bottles with crown caps - one capping head fully automatic unit to capping the aluminium cans - one capping head Operation speed (valid for 330 ml containers) : up to 850 bottles or cans per hour (depending on the operator, product, temperature, foamicity, pressure) Read more »

Compact fully automatic counterpressure filling and capping machine with two integrated units : fully automatic isobaric filling unit for glass bottles and aluminium cans - six electronic valves fully automatic pneumatic capping unit for the bottles with crown caps - one capping head fully automatic unit to capping the aluminium cans - one capping head Operation speed (valid for 330 ml containers) : up to 850 bottles or cans per hour (depending on the operator, product, temperature, foamicity, pressure) Read more »

WordPress RSS Feed Retriever by Theme Mason

Other equipment for filling beverages in bottles and operations associated with bottle filling :

-

Handy bottle filling equipment

-

Semi-automatic bottle rinsing and filling machines – up to 1300 bottles / hr.

-

Bottle rinsing machines

-

Bottle crowning machines

-

Bottle labelling machines

-

Bottle packing machines

-

Bottle handling machines