BREWORX LITE ME | Technical specification of the wort brew machine

BREWORX LITE ME wort brew machine – the simplified brewhouse with a luxury design

The BREWORX LITE ME brewhouse enables the production of virtualy all known types of beer according to Czech and foreign recipes from wort concentrate or malt extract. The conctruction of the machine does not allow the beer production from malt. The brewhouse is suited for the production of beer according to a current offer of the malt extracts producers .

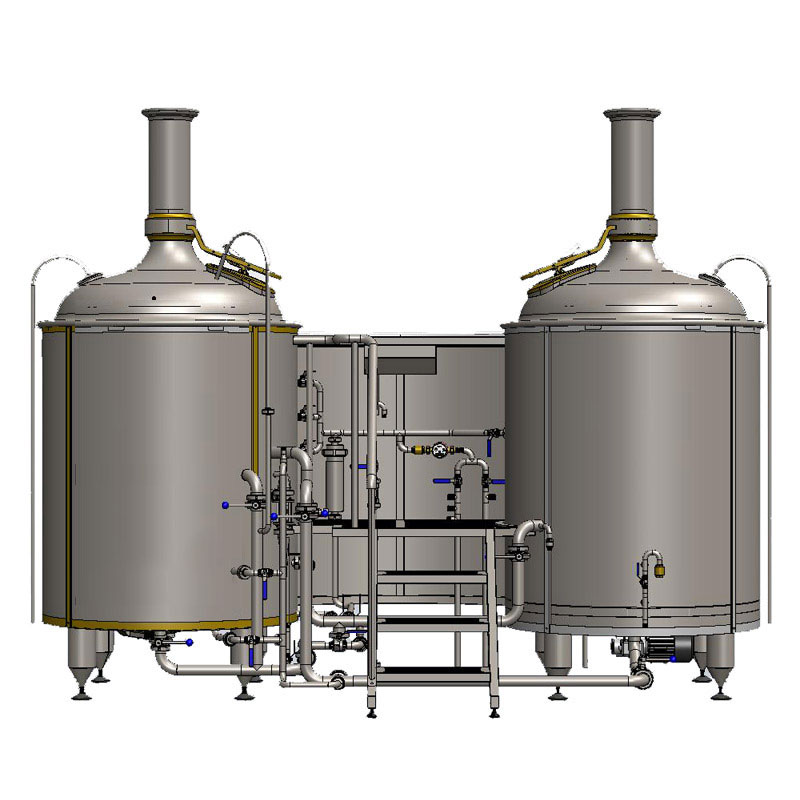

An external appearance of the BREWORX LITE ME brewhouse imitates a luxury interior design of the BREWORX CLASSIC brewhouse. Therefore this model of the brew machine can be placed and operated in interior of the restaurant as well. Luxury traditional design of the complicated wort production machine in the middle of the restaurant is a good marketing tool which pull a customer attention.

A typical feature of BREWORX LITE ME breweries is two main tanks built on a common frame.

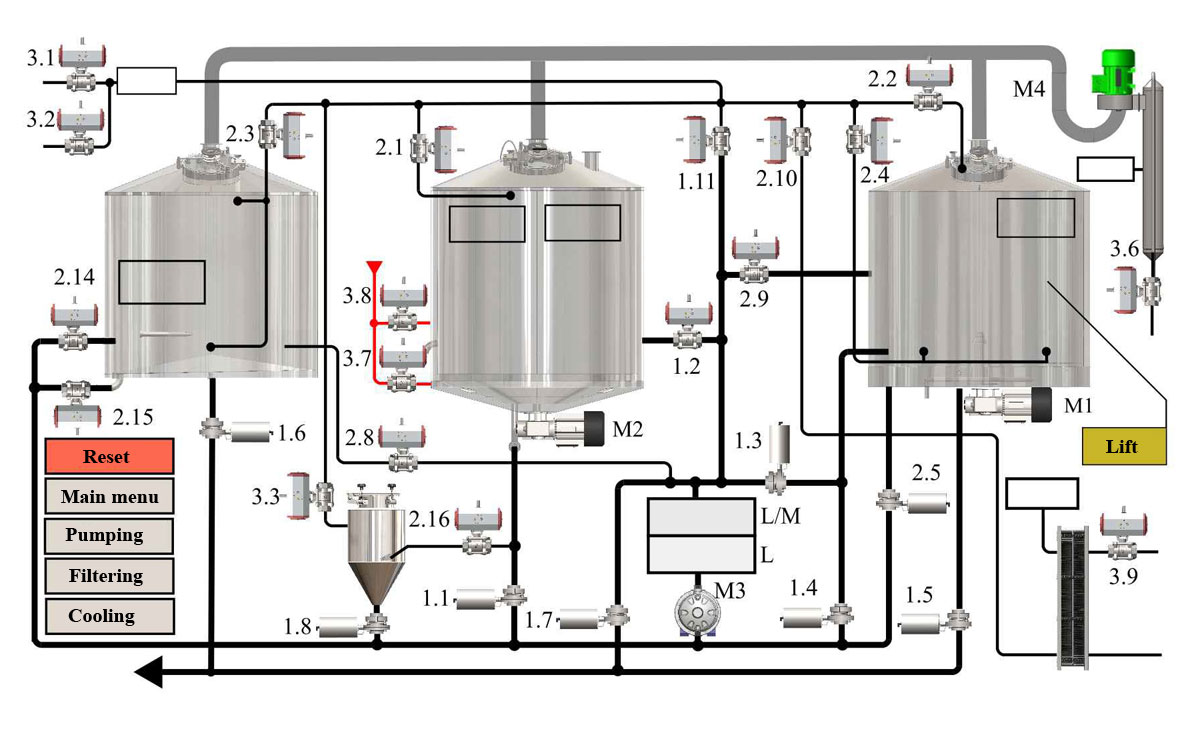

The BREWORX LITE-ME wort brew machine consists of several parts:

1. Malt concentrate boiling tank – heated vessel for the mixing of the malt concentrate in water, boiling of mash from the malt-concentrate .

2. Wort boiling tank – heated vessel for the boiling of wort with hops.

3. Whirlpool tank – a vessel equipped with a tangential inlet for centrifugal separation of solid parts from hopped wort (this vessel may be designed also as an external component of the brewhouse)

– Basic frame with work platform (excluding the smallest brewing machines)

– Pipe system with pumps

– Motors with agitators for mixing and cutting of malt mash

– Wort cooler (may be used as external part)

– Wort-aeration candle (may be used as external part)

– Electric system for measuring and manual or automatic control of the wort brewing process.

The hot water tank and a tank for cold water are optional external accessories of the brewing machine.

Available models of the BREWORX LITE-ME brewhouses

BREWORX LITE-ME craft breweries are delivered with a volume of wort production capacity 1.5 HL – 10 HL per one batch. Total annual production of the microbrewery is then given by the brewing schedule, number and type of fermentation and maturation vessels, number and type of serving tanks, selected range of beer types and other parameters.

- BREWORX LITE-ME 300 : Wort brew machine

The singleblock brewhouse BREWORX LITE-ME 300 is a compact machine which includes all necessary equipment to produce 354 liters of beer wort (for production approximately 300 liters of beer) in one batch from malt extract or wort concentrate (beer concentrates). It is two-vessels brewhouse. The BREWORX LITE-ME 300 brewhouse is simplified machine with similar design like the brewhouse BREWORX CLASSIC 300 . This model of the brewhouse is not equipped for production of beer wort from traditional raw materials (malt instead concentrate). This brewhouse is a main componet of the BREWORX Lite-ME 300 breweries but it can be use with other type… Read more »

The singleblock brewhouse BREWORX LITE-ME 300 is a compact machine which includes all necessary equipment to produce 354 liters of beer wort (for production approximately 300 liters of beer) in one batch from malt extract or wort concentrate (beer concentrates). It is two-vessels brewhouse. The BREWORX LITE-ME 300 brewhouse is simplified machine with similar design like the brewhouse BREWORX CLASSIC 300 . This model of the brewhouse is not equipped for production of beer wort from traditional raw materials (malt instead concentrate). This brewhouse is a main componet of the BREWORX Lite-ME 300 breweries but it can be use with other type… Read more » - BREWORX LITE-ME 600 : Wort brew machine

The singleblock brewhouse BREWORX LITE-ME 600 is a compact machine which includes all necessary equipment to produce 708 liters of beer wort (for production approximately 600 liters of beer) in one batch from malt extract or wort concentrate (beer concentrates). It is two-vessels brewhouse. The BREWORX LITE-ME 600 brewhouse is simplified machine with similar design like the brewhouse BREWORX CLASSIC 600 . This model of the brewhouse is not equipped for production of beer wort from traditional raw materials (malt instead concentrate). This brewhouse is a main componet of the BREWORX Lite-ME 600 breweries but it can be use with other type breweries… Read more »

The singleblock brewhouse BREWORX LITE-ME 600 is a compact machine which includes all necessary equipment to produce 708 liters of beer wort (for production approximately 600 liters of beer) in one batch from malt extract or wort concentrate (beer concentrates). It is two-vessels brewhouse. The BREWORX LITE-ME 600 brewhouse is simplified machine with similar design like the brewhouse BREWORX CLASSIC 600 . This model of the brewhouse is not equipped for production of beer wort from traditional raw materials (malt instead concentrate). This brewhouse is a main componet of the BREWORX Lite-ME 600 breweries but it can be use with other type breweries… Read more » - BREWORX LITE-ME 1000 : Wort brew machine

The singleblock brewhouse BREWORX LITE-ME 1000 is a compact machine which includes all necessary equipment to produce 1180 liters of beer wort (for production approximately 1000 liters of beer) in one batch from malt extract or wort concentrate (beer concentrates). It is two-vessels brewhouse. The BREWORX LITE-ME 1000 brewhouse is simplified machine with similar design like the brewhouse BREWORX CLASSIC 1000 . This model of the brewhouse is not equipped for production of beer wort from traditional raw materials (malt instead concentrate). This brewhouse is a main componet of the BREWORX Lite-ME 1000 breweries but it can be use with other type… Read more »

The singleblock brewhouse BREWORX LITE-ME 1000 is a compact machine which includes all necessary equipment to produce 1180 liters of beer wort (for production approximately 1000 liters of beer) in one batch from malt extract or wort concentrate (beer concentrates). It is two-vessels brewhouse. The BREWORX LITE-ME 1000 brewhouse is simplified machine with similar design like the brewhouse BREWORX CLASSIC 1000 . This model of the brewhouse is not equipped for production of beer wort from traditional raw materials (malt instead concentrate). This brewhouse is a main componet of the BREWORX Lite-ME 1000 breweries but it can be use with other type… Read more »

Description

The wort brew machine is a main device of every brewery. It is a food machine whose function is the production of beer wort. The wort is an intermediate product in the beer production process. The next phase of the production cycle is fermentation and maturation of wort. This is a way to the final beverage.

The BREWORX LITE-ME is the simplified brewhouse with similar design like BREWORX CLASSIC has . But it is designed for production of beer wort only from a malt extract or wort concentrate (water, wort concentrate or malt extract, hops, brewer’s yeast). Warning : This model of the brewhouse is not equipped for production of beer wort from traditional raw materials (malt extract must be used instead malt).

The BREWORX LITE-ME is the simplified brewhouse with similar design like BREWORX CLASSIC has . But it is designed for production of beer wort only from a malt extract or wort concentrate (water, wort concentrate or malt extract, hops, brewer’s yeast). Warning : This model of the brewhouse is not equipped for production of beer wort from traditional raw materials (malt extract must be used instead malt).

Benefits of using the brewhouse BREWORX Lite-ME

- Easy production of wort without having years of operator´s experience and eductaion

- Easy to achieve a stable quality of beer without the influence of variable quality of raw materials

- A malt grind machine is not needed as part of the brewery – therefore safe costs, no problems with storage and preparation of malt grist

- Short learning time for workers in the process production of quality beer

- Possibility of almost complete automation of wort production, which in the production of beer from traditional materials is not economicaly possible

- Significant savings in labor, especially in the automatic version of the brewhouse

- Considerable energy savings up to 50% in the production of wort concentrate

- Reducing the volume of solid waste production by up to 90% – there are no waste malt grains

- Lower purchase price of a fully equipped brewery

- Faster return on investment

Options and properties

Two kinds of beer concentrate for production of wort :

- Wort concentrate : Wort concentrate + drinking water + brewer’s yeast + (optionally other ingrediences)

- Malt extract : Malt extract + hops + drinking water + brewer’s yeast + (optionally other ingrediences)

Four production capacities of the brewhouse :

- 150-1000 liters of beer wort per day – one batch for 12 hour

- 300-2000 liters of beer wort per day – two batches for 24 hour

- 450-3000 liters of beer wort per day – three batches for 12 hour

- 600-4000 liters of beer wort per day – four batches for 24 hour

Two available designs :

- SD – Stainless steel design – all vessels are fully made of stainless steel AISI 304

- CD – Copper design – all main parts are made of stainless steel AISI 304, only outer sheath and hats of containers are made of copper.

Two available heating systems :

- EH – Electric heating – the heating of kettel is performed by electric heating elements without the use of heat transfer fluid. This variation of the brewhouse needn´t a steam generator.

- SH – Steam heating – the heating of kettel is performed by hot steam produced by steam generator. Heating by hot steam significantly speeds up the boiling process and it is better for the heated wort (no caramelization of malt extract). This system requires a connection of the brewhouse to electric, gas or pellet steam generator that is not included in the brewhouse (see an optional accessories).

Two available control systems :

- MC – Manual control – – the brewhouse is manually operated with the support of computer application that guides the user step by step through the production process. Heating of the brewhouse, stirrer speed, the pump running are controlled from a central control panel.

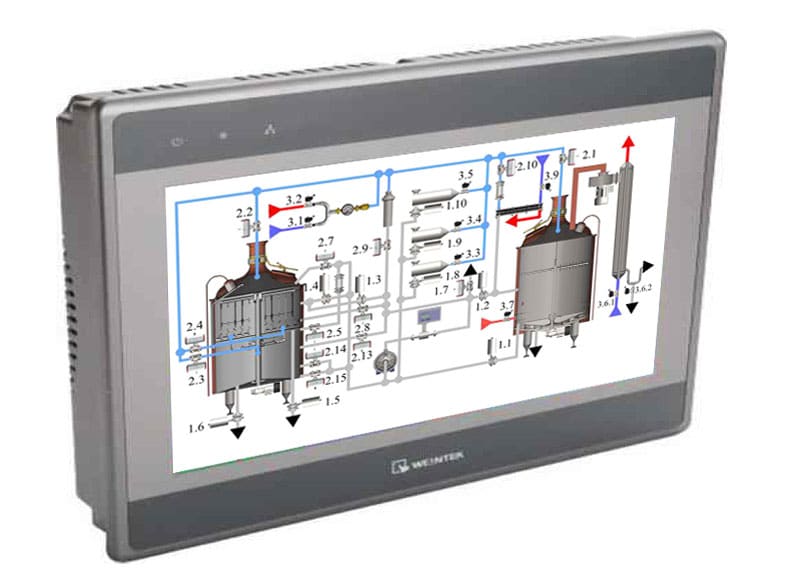

- AC – Automatic control – automatically controlled brewhouse supported by industrial computer which automatically controls the production of wort and requires little user´s interaction. Features such as heating of the brewhouse, stirrer speed, pumps running, valves and control valves are computer controlled and adjusted to a central control panel with touchscreen.

Why choose an automatic system for the brewing control ? Main reasons are :

- Elimination of human errors – machine accurately and timely perform necessary tasks

- Costs saving for owner – only one worker is necessary for manipulating in the brewery

- Minimize the number of error conditions in the brewery – everything is still under control

- Monitoring and registration of the production process into the computer memory

- Minimization of requirements for constant operator attention – early reaction of machine

- Stable quality of beer – standard manufacturing procedures are always observed

- Six pre-programmed recipes – for production of the most known types of beer : Pils, Lager, Black, Weissenbeer, Ale, Special

- Manual brewing mode – for production of all other types of beer

- Special sanitation mode – for automatic cleaning,sanitizing and sterilization of the brewhouse, wort pipes, armatures and other brewery equipment

Recommendation :

We emphatically recommend choose the automatic brewhouse control system for this type of the brewhouse and also the automatic control system for media and fermentation & maturation process !

Brewhouse automatic control system always ensures the right brewing operations timing without damaged wort batches.

Automatic control system for media and fermentation & maturation process – allows automatic monitoring and controlling of the most important parts of beer fermentation and maturation process and operations with media.

How looks the automatic control panel ? This is a main menu. Choose one from several beer types or functions then click and go.

Special functions :

- CIP function – the special mode ensures cleaning, sanitization and sterilization of the brewhouse, wort pipes and optionally also other devices in the brewery

Technical specification

(Example parameters – valid for the BREWORX LITE-ME 500 wort brew machine)

Wort and mash tank – mixing vessel and boiling tank

- Usable capacity 1175 l

- Dimensions Ø 1 240 mm, height 1 300 mm

- Steam bottom area 0,94 m2

- Steam jacketing area 0,36 m2

- Steam valve ASCOjucomatik DN 15

- Steam condensate discharge DN 15

- Four-arm agitator with gearbox output power 650 Nm, input power 2,2 kW

- Lighting 12V 35W

- 2x Sanitary rotating shower DN 25

- Steamer DN 100, 3x spraying device

- Insulation 40 mm plasticized cotton,

- external jacketing copper 1 mm

- Top cover in copper + steamer imitation DN 200

- Measuring rod with ČMI-cz certification/directive 71/316/EEC

Hot water tank / Whirlpool

- Usable capacity 1175 l

- Dimensions Ø 1 240 mm, height 560 mm

- Filtration bottom 6 segments with 12% permeability

- Nozzles for rinsing under wire 3 pc

- Stirrer 2 arms, 8 blades

- Gearbox 640 Nm, input power 2200W

- Lighting 12V 35W

- Mechanical temperature indicator 0-120ºC stainless steel

- 1x Sanitary rotating shower RTS 25

- Three-way setting valve with sight glass DN 50

- Tangential nozzle DN 20

- Level indicator DN 20

- Fermenting valve 2x DN 25

- Insulation 40 mm plasticized cotton,

- external jacketing copper 1 mm

- Top cover in copper + steamer imitation DN 150 (only for CD design version)

Piping, armatures

- Primary line DN 40, 4x flap valve DN 50

- Drain line DN 40, 2x flap valve DN 50

- Sanitary line DN 25, 3x valve DN 25

- Water supply and additional lines DN 25, 5x valve DN 25

- Beer wort filter 2000l/h/DN 80

- Mashing /fermentation pump DWO 150 Ebara

- Input power 750W

- H max. 2,2 bar

- pump controlled by frequency converter Fronic 1.5 kW

Electric installation

- Main switch 3x25A with central stop button

- Motor starter 3x 2.5-4A

- 1x Frequency converter Fronic mini 1.5 kW

- 1x Frequency converter Fronic mini 0.75 kW

- Digital temperature regulator of mash kettle Dixel XR20D

- Digital regulator of beer wort output temperature Dixel XR20D

- Circuit breaker 6A 230V

- Circuit breaker 10A 230V

- Circuit breaker 4A 230V

- Plastic DIN switchboard, 36 modules

- Wiring

- 5x 1,5 18 m

- 5x 2.5 10 m

- 3x 1 48 m

Dimensions and weight

- Weight 930 kg

- Basic size minimum height 2 700 mm

- Width 3 800 mm

- Depth 2 030 mm

This boiling equipment is mounted in a rigid frame made of 1.4301, 8 pc adjustable supports installed in its bottom part.

Connections:

- Beer wort discharge DN 25

- Cold water supply DN 25

- Hot water supply DN 25

- Drain line DN 50

- Electro 5x 2,5 5000 W

Auxiliaries:

- Wash basin with combined lever taps assembly

- Cooling device for samples

- Flow meter DN 25 of water supply

- Water filter

- Combined water taps assembly with digital indication of temperatures

- Steps to service bridge 750*730*585 mm

Transport

This equipment is usually shipped in assembled state with exception for copper covers, steamer for steam condensation, steps of service bridge and electric switchboard.

Optional accessories

- ACS – Automatic control system – automatic brewing process of wort fully controlles by computer

- STG – Steam generator – necessary only for version with SH heating system

- WCS – Wort cooling system – equipment for controlled hot wort cooling to the fermentation temperature (7°C or 25°C depending on the type of beer)

- MMG – Malt mill – equipment for grinding of malt – necessary only for production of wort from malt (not necessary for production of wort from malt extract)

- LEA – Laboratory equipment and accessories – saccharimeters, alcoholmeters, graduated cylinder, wooden rod for manual level measurement

- HWT – Heat water tank – insulated vessel for storaging of heat water purchased from wort cooling process. It is necessary to have hot water available for some parts of boiling cycle in the brewhouse.

- ITWT – Ice treated water tank – insulated vessel for cooling, storaging and pumping of ice water which is necessary in wort cooling process. This treated drinking ice water is heated in wort cooling process and becomes then hot water storaged in HWT. If is not available drinking water with requested chemical composition, it is needed to use some equipment for water treatment – WTS. Available for breweries with one-level wort cooling system – we recomment it for brewhouses with production capacity above 1000 liters of wort per one brew instead ICWT.

- ICWT – Ice cooling water tank – insulated vessel for cooling, storaging and pumping of ice water which is necessary in wort cooling process. This treated drinking ice water is heated in wort cooling process and then is comming back to the cooling system. Available for breweries with two-level wort cooling system – we recomment it for brewhouses with production capacity max.1000 liters of wort per one brew instead ITWT.

- WTS – Water treatment systems – equipment for treating of cold water that has not requested chemical composition available for brewing of choosed type beer. It is needed a chemical analysis for assessment of suitable water chemical composition.

Optional services

BTS – Brewer´s training services for starting of a new microbrewery and also for already operating microbreweries – all courses are teached by certificated Czech brewer in Czechia or in the country of the customer.

Recommended accessories for the brewhouses BREWORX LITE-ME

We offer useful accessories for the brewhouse BREWORX LITE-ME :

Automatic control system

- BHAC-1 : Automatic Control System for brewhouses Classic, Lite-ME, Tritank 300L-1000L

The BHAC1 is automatic control system for brewhouse with computer support and most operations controlled automatically - according to a specified program from a central control panel. This control system cooperates with our brewhouses Breworx Classic, Breworx Lite-ME and Breworx Tritank with usable volumes from 150 to 1000 liters. Read more »

The BHAC1 is automatic control system for brewhouse with computer support and most operations controlled automatically - according to a specified program from a central control panel. This control system cooperates with our brewhouses Breworx Classic, Breworx Lite-ME and Breworx Tritank with usable volumes from 150 to 1000 liters. Read more » - BHAC-2 : Automatic Control System for brewhouses Classic, Lite-ME, Tritank1200L-5000L

The BHAC2 is automatic control system for brewhouse with computer support and most operations controlled automatically - according to a specified program from a central control panel. This control system cooperates with our brewhouses Breworx Classic, Breworx Lite-ME and Breworx Tritank with usable volumes from 1200 to 5000 liters. Read more »

The BHAC2 is automatic control system for brewhouse with computer support and most operations controlled automatically - according to a specified program from a central control panel. This control system cooperates with our brewhouses Breworx Classic, Breworx Lite-ME and Breworx Tritank with usable volumes from 1200 to 5000 liters. Read more » - BHAC-6 : Automatic Control System for brewhouses Oppidum 1000L-6000L

The BHAC-6 is an automatic control system for the OPPIDUM wort preparation machines with computer support and most operations controlled automatically – according to a specified program from a central control panel. This control system cooperates with OPPIDUM machines with usable production volumes from 1000 up to 6000 liters of wort per one batch. BHAC3 automatic control system for the brewery includes: Automatically controlled hot process of brewing – fully automatized management of the entire processes of production wort Automatic system for time-control of temperatures in fermentation and maturation process Automatic system for control of media Read more »

The BHAC-6 is an automatic control system for the OPPIDUM wort preparation machines with computer support and most operations controlled automatically – according to a specified program from a central control panel. This control system cooperates with OPPIDUM machines with usable production volumes from 1000 up to 6000 liters of wort per one batch. BHAC3 automatic control system for the brewery includes: Automatically controlled hot process of brewing – fully automatized management of the entire processes of production wort Automatic system for time-control of temperatures in fermentation and maturation process Automatic system for control of media Read more » - BHAC-2C : Brewhouse Breworx Automatic Control System with customization

The BHAC2C is automatic control system for brewhouse with computer support and most operations controlled automatically - according to a specified program from a central control panel. This control system cooperates with our brewhouses Breworx Classic, Breworx Lite-ME and Breworx Tritank with usable volumes from 1200 to 5000 liters. This version is calculated for a customization of standard version of BHAC2 system according to special customer´s requirements. Read more »

The BHAC2C is automatic control system for brewhouse with computer support and most operations controlled automatically - according to a specified program from a central control panel. This control system cooperates with our brewhouses Breworx Classic, Breworx Lite-ME and Breworx Tritank with usable volumes from 1200 to 5000 liters. This version is calculated for a customization of standard version of BHAC2 system according to special customer´s requirements. Read more » - BHAC-1C : Brewhouse Breworx Automatic Control System with customization

The BHAC1 is automatic control system for brewhouse with computer support and most operations controlled automatically - according to a specified program from a central control panel. This control system cooperates with our brewhouses Breworx Classic, Breworx Lite-ME and Breworx Tritank with usable volumes from 150 to 1000 liters. This version is calculated for a customization of standard version of BHAC1 system according to special customer´s requirements. Read more »

The BHAC1 is automatic control system for brewhouse with computer support and most operations controlled automatically - according to a specified program from a central control panel. This control system cooperates with our brewhouses Breworx Classic, Breworx Lite-ME and Breworx Tritank with usable volumes from 150 to 1000 liters. This version is calculated for a customization of standard version of BHAC1 system according to special customer´s requirements. Read more » - BHAC-6C Brewhouse Oppidum Automatic Control System with customization

The BHAC3 is an automatic control system for the OPPIDUM wort preparation machines with computer support and most operations controlled automatically – according to a specified program from a central control panel. This control system cooperates with OPPIDUM machines with usable production volumes from 1000 up to 5000 liters of wort per one batch. This version is calculated for a customization of standard version of BHAC3 system according to special customer´s requirements. BHAC3C - the automatic control system for the wort production machine OPPIDUM includes: Automatically controlled hot process of brewing – fully automatized management of the entire processes of… Read more »

The BHAC3 is an automatic control system for the OPPIDUM wort preparation machines with computer support and most operations controlled automatically – according to a specified program from a central control panel. This control system cooperates with OPPIDUM machines with usable production volumes from 1000 up to 5000 liters of wort per one batch. This version is calculated for a customization of standard version of BHAC3 system according to special customer´s requirements. BHAC3C - the automatic control system for the wort production machine OPPIDUM includes: Automatically controlled hot process of brewing – fully automatized management of the entire processes of… Read more » - BHAC-4 Automatic Control System for brewhouses Quadrant 1000L-5000L

The BHAC4 is automatic control system for brewhouse with computer support and most operations controlled automatically - according to a specified program from a central control panel. This control system cooperates with our brewhouses QUADRANT with usable volumes from 1000 to 5000 liters. Read more »

The BHAC4 is automatic control system for brewhouse with computer support and most operations controlled automatically - according to a specified program from a central control panel. This control system cooperates with our brewhouses QUADRANT with usable volumes from 1000 to 5000 liters. Read more » - BHSA-1 : Semi-Automatic Control System for brewhouses Classic, Lite-ME, Tritank 150L-1000L (with complete control via touch LCD)

The semi-automatic control system with complete control via touch LCD for the brewhouses Breworx Classic, Lite-ME, Tritank 150L-1000L (upgradeable to the fully automatic system). All valves are controlleable via the touch LCD panel, several operations are controlled automatically - according to a specified program. This control system cooperates with our brewhouses Breworx Classic, Breworx Lite-ME and Breworx Tritank with nominal volumes from 150 to 1000 liters. The semi-automation of the brewing machine is supplied as part of the brewhouse, but is not included in its basic price. Read more »

The semi-automatic control system with complete control via touch LCD for the brewhouses Breworx Classic, Lite-ME, Tritank 150L-1000L (upgradeable to the fully automatic system). All valves are controlleable via the touch LCD panel, several operations are controlled automatically - according to a specified program. This control system cooperates with our brewhouses Breworx Classic, Breworx Lite-ME and Breworx Tritank with nominal volumes from 150 to 1000 liters. The semi-automation of the brewing machine is supplied as part of the brewhouse, but is not included in its basic price. Read more » - BHSA-2 : Semi-Automatic Control System for brewhouses Classic, Lite-ME, Tritank 1200L-5000L (with complete control via touch LCD)

The semi-automatic control system with complete control via touch LCD for the brewhouses Breworx Classic, Lite-ME, Tritank 1200L-5000L (upgradeable to the fully automatic system). All valves are controlleable via the touch LCD panel, several operations are controlled automatically - according to a specified program. This control system cooperates with our brewhouses Breworx Classic, Breworx Lite-ME and Breworx Tritank with nominal volumes from 1200 to 5000 liters. The semi-automation of the brewing machine is supplied as part of the brewhouse, but is not included in its basic price. Read more »

The semi-automatic control system with complete control via touch LCD for the brewhouses Breworx Classic, Lite-ME, Tritank 1200L-5000L (upgradeable to the fully automatic system). All valves are controlleable via the touch LCD panel, several operations are controlled automatically - according to a specified program. This control system cooperates with our brewhouses Breworx Classic, Breworx Lite-ME and Breworx Tritank with nominal volumes from 1200 to 5000 liters. The semi-automation of the brewing machine is supplied as part of the brewhouse, but is not included in its basic price. Read more »

Vapor condenser

- BVP-1000 : Brewhouse vapor condenser with the heat recuperation

This equipment is used for condensation and removal of vapors generated in boiling equipment during the brewing process.The vapor condenser BVP-1000 allows suction of vapor from the container by ventilator and subsequent condensation in a tubular heat exchanger. From the heat exchanger then goes only condensed liquid of substantially lower temperature, which do not shorten the lifetime of the waste-pipe of the brewhouse. Drinking hot water (as coolant) outgoing from the heat exchanger is able to be collected in the hot water tank for later use. Read more »

This equipment is used for condensation and removal of vapors generated in boiling equipment during the brewing process.The vapor condenser BVP-1000 allows suction of vapor from the container by ventilator and subsequent condensation in a tubular heat exchanger. From the heat exchanger then goes only condensed liquid of substantially lower temperature, which do not shorten the lifetime of the waste-pipe of the brewhouse. Drinking hot water (as coolant) outgoing from the heat exchanger is able to be collected in the hot water tank for later use. Read more » - BVP-600 : Brewhouse vapor condenser with the heat recuperation

This equipment is used for condensation and removal of vapors generated in boiling equipment during the brewing process.The vapor condenser BVP-600 allows suction of vapor from the container by ventilator and subsequent condensation in a tubular heat exchanger. From the heat exchanger then goes only condensed liquid of substantially lower temperature, which do not shorten the lifetime of the waste-pipe of the brewhouse. Drinking hot water (as coolant) outgoing from the heat exchanger is able to be collected in the hot water tank for later use. Read more »

This equipment is used for condensation and removal of vapors generated in boiling equipment during the brewing process.The vapor condenser BVP-600 allows suction of vapor from the container by ventilator and subsequent condensation in a tubular heat exchanger. From the heat exchanger then goes only condensed liquid of substantially lower temperature, which do not shorten the lifetime of the waste-pipe of the brewhouse. Drinking hot water (as coolant) outgoing from the heat exchanger is able to be collected in the hot water tank for later use. Read more » - BVP-250 : Brewhouse vapor condenser with the heat recuperation

This equipment is used for condensation and removal of vapors generated in boiling equipment during the brewing process.The vapor condenser BVP-250 allows suction of vapor from the container by ventilator and subsequent condensation in a tubular heat exchanger. From the heat exchanger then goes only condensed liquid of substantially lower temperature, which do not shorten the lifetime of the waste-pipe of the brewhouse. Drinking hot water (as coolant) outgoing from the heat exchanger is able to be collected in the hot water tank for later use. Read more »

This equipment is used for condensation and removal of vapors generated in boiling equipment during the brewing process.The vapor condenser BVP-250 allows suction of vapor from the container by ventilator and subsequent condensation in a tubular heat exchanger. From the heat exchanger then goes only condensed liquid of substantially lower temperature, which do not shorten the lifetime of the waste-pipe of the brewhouse. Drinking hot water (as coolant) outgoing from the heat exchanger is able to be collected in the hot water tank for later use. Read more » - BVP-400 : Brewhouse vapor condenser with the heat recuperation

This equipment is used for condensation and removal of vapors generated in boiling equipment during the brewing process.The vapor condenser BVP-400 allows suction of vapor from the container by ventilator and subsequent condensation in a tubular heat exchanger. From the heat exchanger then goes only condensed liquid of substantially lower temperature, which do not shorten the lifetime of the waste-pipe of the brewhouse. Drinking hot water (as coolant) outgoing from the heat exchanger is able to be collected in the hot water tank for later use. Read more »

This equipment is used for condensation and removal of vapors generated in boiling equipment during the brewing process.The vapor condenser BVP-400 allows suction of vapor from the container by ventilator and subsequent condensation in a tubular heat exchanger. From the heat exchanger then goes only condensed liquid of substantially lower temperature, which do not shorten the lifetime of the waste-pipe of the brewhouse. Drinking hot water (as coolant) outgoing from the heat exchanger is able to be collected in the hot water tank for later use. Read more » - BVP-2000 : Brewhouse vapor condenser with the heat recuperation

This equipment is used for condensation and removal of vapors generated in boiling equipment during the brewing process.The vapor condenser BVP-2000 allows suction of vapor from the container by ventilator and subsequent condensation in a tubular heat exchanger. From the heat exchanger then goes only condensed liquid of substantially lower temperature, which do not shorten the lifetime of the waste-pipe of the brewhouse. Drinking hot water (as coolant) outgoing from the heat exchanger is able to be collected in the hot water tank for later use. Read more »

This equipment is used for condensation and removal of vapors generated in boiling equipment during the brewing process.The vapor condenser BVP-2000 allows suction of vapor from the container by ventilator and subsequent condensation in a tubular heat exchanger. From the heat exchanger then goes only condensed liquid of substantially lower temperature, which do not shorten the lifetime of the waste-pipe of the brewhouse. Drinking hot water (as coolant) outgoing from the heat exchanger is able to be collected in the hot water tank for later use. Read more » - BVP-3000 : Brewhouse vapor condenser with the heat recuperation

This equipment is used for condensation and removal of vapors generated in boiling equipment during the brewing process.The vapor condenser BVP-3000 allows suction of vapor from the container by ventilator and subsequent condensation in a tubular heat exchanger. From the heat exchanger then goes only condensed liquid of substantially lower temperature, which do not shorten the lifetime of the waste-pipe of the brewhouse. Drinking hot water (as coolant) outgoing from the heat exchanger is able to be collected in the hot water tank for later use. The BVP-3000 set includes two the same independent vapor condensers. Read more »

This equipment is used for condensation and removal of vapors generated in boiling equipment during the brewing process.The vapor condenser BVP-3000 allows suction of vapor from the container by ventilator and subsequent condensation in a tubular heat exchanger. From the heat exchanger then goes only condensed liquid of substantially lower temperature, which do not shorten the lifetime of the waste-pipe of the brewhouse. Drinking hot water (as coolant) outgoing from the heat exchanger is able to be collected in the hot water tank for later use. The BVP-3000 set includes two the same independent vapor condensers. Read more » - BVP-4000 : Brewhouse vapor condenser with the heat recuperation

This equipment is used for condensation and removal of vapors generated in boiling equipment during the brewing process.The vapor condenser BVP-4000 allows suction of vapor from the container by ventilator and subsequent condensation in a tubular heat exchanger. From the heat exchanger then goes only condensed liquid of substantially lower temperature, which do not shorten the lifetime of the waste-pipe of the brewhouse. Drinking hot water (as coolant) outgoing from the heat exchanger is able to be collected in the hot water tank for later use. The BVP-4000 set includes two the same independent vapor condensers. Read more »

This equipment is used for condensation and removal of vapors generated in boiling equipment during the brewing process.The vapor condenser BVP-4000 allows suction of vapor from the container by ventilator and subsequent condensation in a tubular heat exchanger. From the heat exchanger then goes only condensed liquid of substantially lower temperature, which do not shorten the lifetime of the waste-pipe of the brewhouse. Drinking hot water (as coolant) outgoing from the heat exchanger is able to be collected in the hot water tank for later use. The BVP-4000 set includes two the same independent vapor condensers. Read more » - BVP-1500 : Brewhouse vapor condenser with the heat recuperation

This equipment is used for condensation and removal of vapors generated in boiling equipment during the brewing process.The vapor condenser BVP-1500 allows suction of vapor from the container by ventilator and subsequent condensation in a tubular heat exchanger. From the heat exchanger then goes only condensed liquid of substantially lower temperature, which do not shorten the lifetime of the waste-pipe of the brewhouse. Drinking hot water (as coolant) outgoing from the heat exchanger is able to be collected in the hot water tank for later use. Read more »

This equipment is used for condensation and removal of vapors generated in boiling equipment during the brewing process.The vapor condenser BVP-1500 allows suction of vapor from the container by ventilator and subsequent condensation in a tubular heat exchanger. From the heat exchanger then goes only condensed liquid of substantially lower temperature, which do not shorten the lifetime of the waste-pipe of the brewhouse. Drinking hot water (as coolant) outgoing from the heat exchanger is able to be collected in the hot water tank for later use. Read more »

Electric steam generators

- TSE-600 : Electric steam generator 300-600 kW | 390-780 kg/hr | 5,5-11.5 bar

Automatic electric hot steam-generator with capacity from 300 kW up to 600 kW (from 390 up to 780 kg of hot steam per hour) Water feed can be connected directly to the water mains or to a condensate tank. Regulation of the working steam pressure is adjustable in range from 1 to 5.5 bar (version 5B) or from 1 to 11.5 bar (version 11B). This steam-generator is available with eight heaters (20x 30 kW) . The steam-generator shell is manufactured in accordance to the current PED CE regulations (PED 2014/68/EU). Made in EU Read more »

Automatic electric hot steam-generator with capacity from 300 kW up to 600 kW (from 390 up to 780 kg of hot steam per hour) Water feed can be connected directly to the water mains or to a condensate tank. Regulation of the working steam pressure is adjustable in range from 1 to 5.5 bar (version 5B) or from 1 to 11.5 bar (version 11B). This steam-generator is available with eight heaters (20x 30 kW) . The steam-generator shell is manufactured in accordance to the current PED CE regulations (PED 2014/68/EU). Made in EU Read more » - MOSG-12E : Mobile electric steam generator 12 kW | 18 kg/hr | 0.7 bar

The mobile steam generator with the heating capacity of 12kW is conceived for the production of hot steam which is needed for cleansing and steam sterilisation of stainless steel tanks, barrels, pipe systemsand fittings, filters and beverage filling units. Maximal operation pressure of steam is 0.7 bar (temperature of 115°C) . Production capacity is approximaly 18 kg of steam per hour. The steam production unit is made of stainless steel. Read more »

The mobile steam generator with the heating capacity of 12kW is conceived for the production of hot steam which is needed for cleansing and steam sterilisation of stainless steel tanks, barrels, pipe systemsand fittings, filters and beverage filling units. Maximal operation pressure of steam is 0.7 bar (temperature of 115°C) . Production capacity is approximaly 18 kg of steam per hour. The steam production unit is made of stainless steel. Read more » - MOSG-18E : Mobile electric steam generator 18 kW | 27 kg/hr | 0.7 bar

The mobile steam generator with the heating capacity of 18kW is conceived for the production of hot steam which is needed for cleansing and steam sterilisation of stainless steel tanks, barrels, pipe systemsand fittings, filters and beverage filling units. Maximal operation pressure of steam is 0.7 bar (temperature of 115°C) . Production capacity is approximaly 27 kg of steam per hour. The steam production unit is made of stainless steel. Read more »

The mobile steam generator with the heating capacity of 18kW is conceived for the production of hot steam which is needed for cleansing and steam sterilisation of stainless steel tanks, barrels, pipe systemsand fittings, filters and beverage filling units. Maximal operation pressure of steam is 0.7 bar (temperature of 115°C) . Production capacity is approximaly 27 kg of steam per hour. The steam production unit is made of stainless steel. Read more » - MOSG-24E : Mobile electric steam generator 24 kW | 36 kg/hr | 0.7 bar

The mobile steam generator with the heating capacity of 24kW is conceived for the production of hot steam which is needed for cleansing and steam sterilisation of stainless steel tanks, barrels, pipe systemsand fittings, filters and beverage filling units. Maximal operation pressure of steam is 0.7 bar (temperature of 115°C) . Production capacity is approximaly 36 kg of steam per hour. The steam production unit is made of stainless steel. Read more »

The mobile steam generator with the heating capacity of 24kW is conceived for the production of hot steam which is needed for cleansing and steam sterilisation of stainless steel tanks, barrels, pipe systemsand fittings, filters and beverage filling units. Maximal operation pressure of steam is 0.7 bar (temperature of 115°C) . Production capacity is approximaly 36 kg of steam per hour. The steam production unit is made of stainless steel. Read more » - SSFS-MX12 : Complete set of stainless steel accessories for achieve pure steam (culinary quality) for 1/2″ steam pipe line

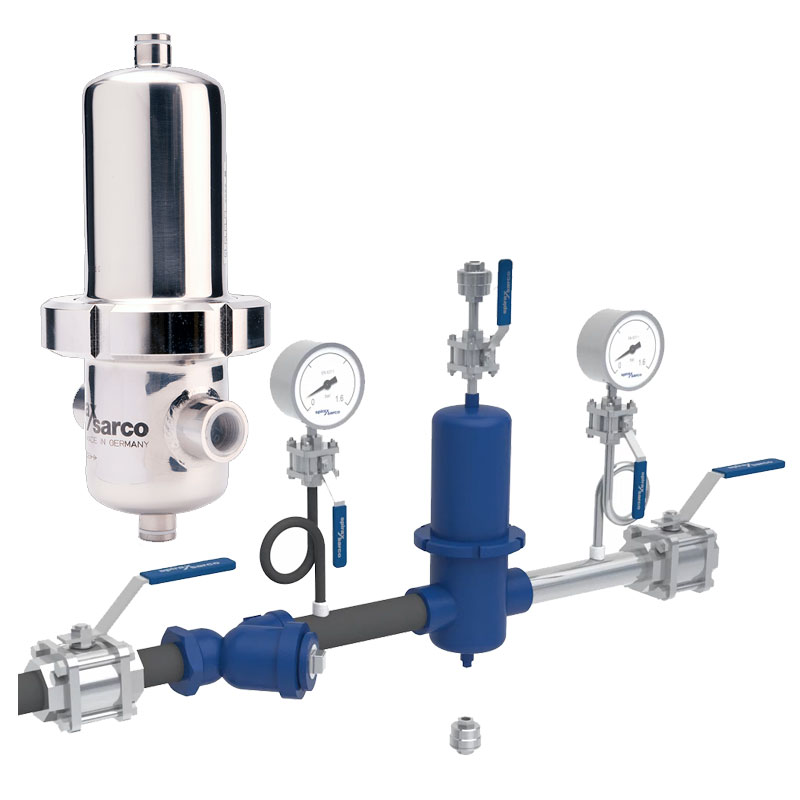

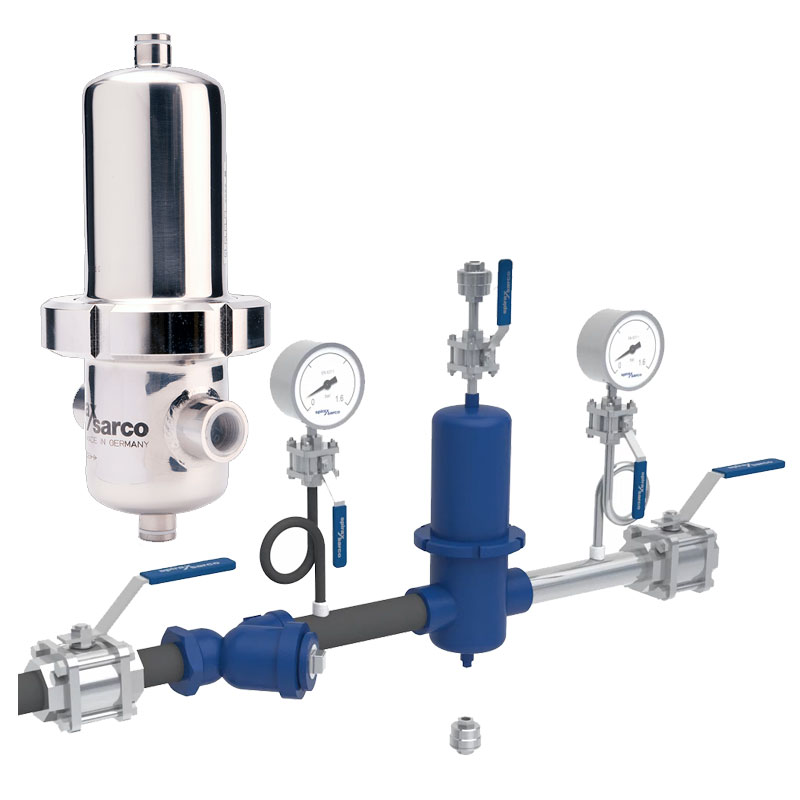

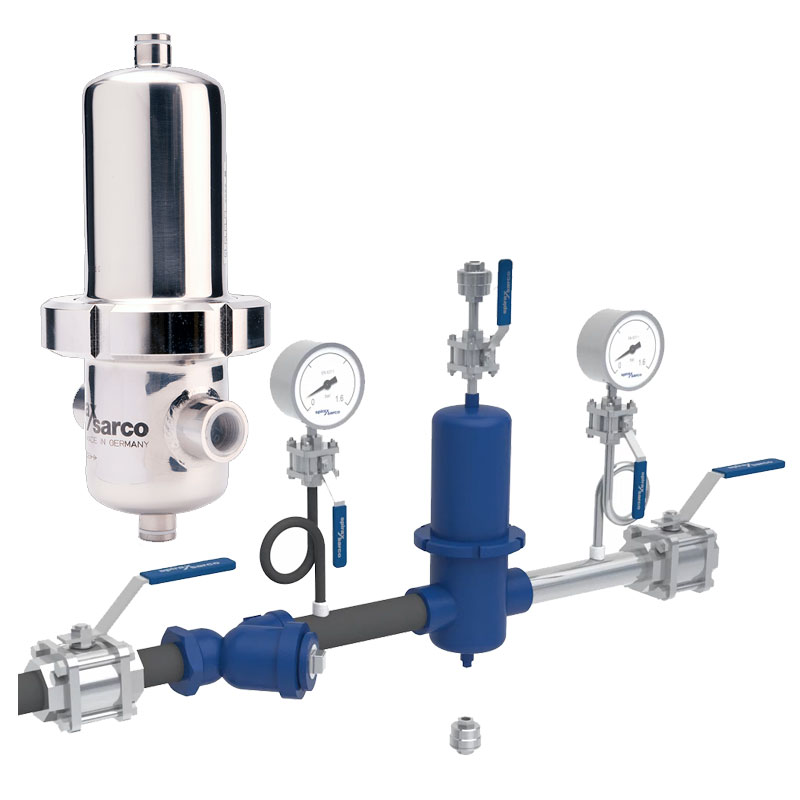

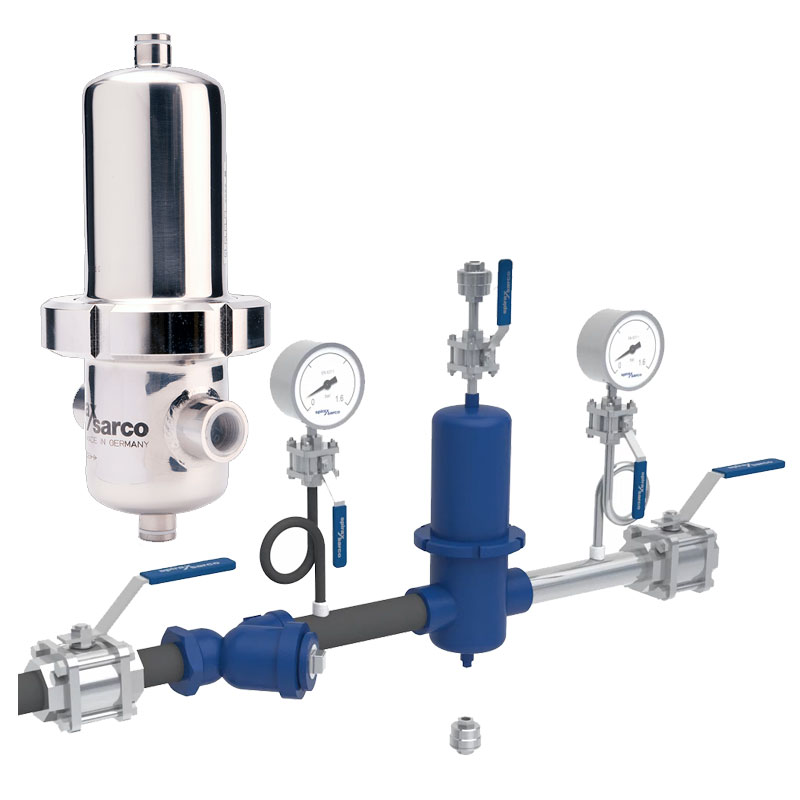

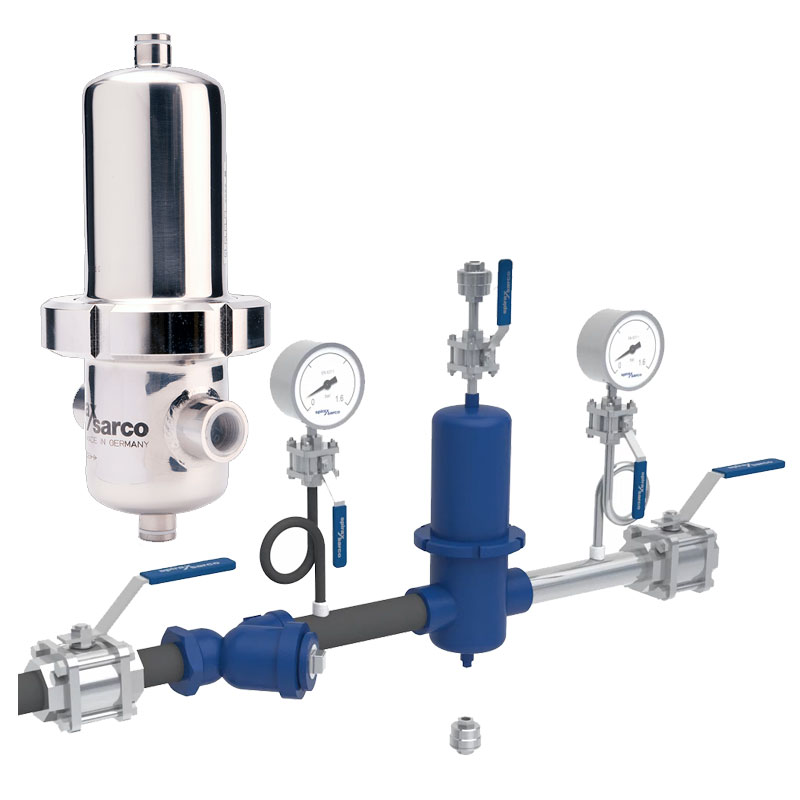

Complete set of stainless steel accessories for achieve pure steam (in culinary quality - for direct contact with food) based on the Spirax Sarco CSF16 Culinary Steam Filter, intended for a 1/2" steam pipe line. Intended for maximal steam pressure of 12 bar. Read more »

Complete set of stainless steel accessories for achieve pure steam (in culinary quality - for direct contact with food) based on the Spirax Sarco CSF16 Culinary Steam Filter, intended for a 1/2" steam pipe line. Intended for maximal steam pressure of 12 bar. Read more » - SSFS-MX34 : Complete set of stainless steel accessories for achieve pure steam (culinary quality) for 3/4″ steam pipe line

Complete set of stainless steel accessories for achieve pure steam (in culinary quality - for direct contact with food) based on the Spirax Sarco CSF16 Culinary Steam Filter, intended for a 3/4" steam pipe line. Intended for maximal steam pressure of 12 bar. Read more »

Complete set of stainless steel accessories for achieve pure steam (in culinary quality - for direct contact with food) based on the Spirax Sarco CSF16 Culinary Steam Filter, intended for a 3/4" steam pipe line. Intended for maximal steam pressure of 12 bar. Read more » - SSFS-MX44 : Complete set of stainless steel accessories for achieve pure steam (culinary quality) for 1″ steam pipe line

Complete set of stainless steel accessories for achieve pure steam (in culinary quality - for direct contact with food) based on the Spirax Sarco CSF16 Culinary Steam Filter, intended for a 1" steam pipe line. Intended for maximal steam pressure of 12 bar. Read more »

Complete set of stainless steel accessories for achieve pure steam (in culinary quality - for direct contact with food) based on the Spirax Sarco CSF16 Culinary Steam Filter, intended for a 1" steam pipe line. Intended for maximal steam pressure of 12 bar. Read more » - SSFS-MX54 : Complete set of stainless steel accessories for achieve pure steam (culinary quality) for 1 1/4″ steam pipe line

Complete set of stainless steel accessories for achieve pure steam (in culinary quality - for direct contact with food) based on the Spirax Sarco CSF16 Culinary Steam Filter, intended for a 1 1/4" steam pipe line. Intended for maximal steam pressure of 12 bar. Read more »

Complete set of stainless steel accessories for achieve pure steam (in culinary quality - for direct contact with food) based on the Spirax Sarco CSF16 Culinary Steam Filter, intended for a 1 1/4" steam pipe line. Intended for maximal steam pressure of 12 bar. Read more » - SSFS-MX64 : Complete set of stainless steel accessories for achieve pure steam (culinary quality) for 1 1/2″ steam pipe line

Complete set of stainless steel accessories for achieve pure steam (in culinary quality - for direct contact with food) based on the Spirax Sarco CSF16 Culinary Steam Filter, intended for a 1 1/2" steam pipe line. Intended for maximal steam pressure of 12 bar. Read more »

Complete set of stainless steel accessories for achieve pure steam (in culinary quality - for direct contact with food) based on the Spirax Sarco CSF16 Culinary Steam Filter, intended for a 1 1/2" steam pipe line. Intended for maximal steam pressure of 12 bar. Read more » - SSFS-MX84 : Complete set of stainless steel accessories for achieve pure steam (culinary quality) for 2″ steam pipe line

Complete set of stainless steel accessories for achieve pure steam (in culinary quality - for direct contact with food) based on the Spirax Sarco CSF16 Culinary Steam Filter, intended for a 2" steam pipe line. Intended for maximal steam pressure of 12 bar. Read more »

Complete set of stainless steel accessories for achieve pure steam (in culinary quality - for direct contact with food) based on the Spirax Sarco CSF16 Culinary Steam Filter, intended for a 2" steam pipe line. Intended for maximal steam pressure of 12 bar. Read more »

Gas steam generators

- SSFS-MX54 : Complete set of stainless steel accessories for achieve pure steam (culinary quality) for 1 1/4″ steam pipe line

Complete set of stainless steel accessories for achieve pure steam (in culinary quality - for direct contact with food) based on the Spirax Sarco CSF16 Culinary Steam Filter, intended for a 1 1/4" steam pipe line. Intended for maximal steam pressure of 12 bar. Read more »

Complete set of stainless steel accessories for achieve pure steam (in culinary quality - for direct contact with food) based on the Spirax Sarco CSF16 Culinary Steam Filter, intended for a 1 1/4" steam pipe line. Intended for maximal steam pressure of 12 bar. Read more » - SSFS-MX64 : Complete set of stainless steel accessories for achieve pure steam (culinary quality) for 1 1/2″ steam pipe line

Complete set of stainless steel accessories for achieve pure steam (in culinary quality - for direct contact with food) based on the Spirax Sarco CSF16 Culinary Steam Filter, intended for a 1 1/2" steam pipe line. Intended for maximal steam pressure of 12 bar. Read more »

Complete set of stainless steel accessories for achieve pure steam (in culinary quality - for direct contact with food) based on the Spirax Sarco CSF16 Culinary Steam Filter, intended for a 1 1/2" steam pipe line. Intended for maximal steam pressure of 12 bar. Read more » - SSFS-MX84 : Complete set of stainless steel accessories for achieve pure steam (culinary quality) for 2″ steam pipe line

Complete set of stainless steel accessories for achieve pure steam (in culinary quality - for direct contact with food) based on the Spirax Sarco CSF16 Culinary Steam Filter, intended for a 2" steam pipe line. Intended for maximal steam pressure of 12 bar. Read more »

Complete set of stainless steel accessories for achieve pure steam (in culinary quality - for direct contact with food) based on the Spirax Sarco CSF16 Culinary Steam Filter, intended for a 2" steam pipe line. Intended for maximal steam pressure of 12 bar. Read more » - GSG-AS600 : Gas steam-generator ANFRA A.S. 422 kW | 600kg/hr | 12 bar

Automatic gas steam-generator, available heating power of 422 kW - The production capacity 600 kg of hot steam per hour. Water feed can be connected directly to the water mains (if water is enough soft, maximaly 5°dH) or to a water treatment and the water / condensate mixing buffer tank. Regulation of the working steam pressure is adjustable in range from 1 up to 11.76 bar. The steam generator fulfils the requirements of the PED Directive 97/23/EC for pressure equipment. Produced in EU Read more »

Automatic gas steam-generator, available heating power of 422 kW - The production capacity 600 kg of hot steam per hour. Water feed can be connected directly to the water mains (if water is enough soft, maximaly 5°dH) or to a water treatment and the water / condensate mixing buffer tank. Regulation of the working steam pressure is adjustable in range from 1 up to 11.76 bar. The steam generator fulfils the requirements of the PED Directive 97/23/EC for pressure equipment. Produced in EU Read more » - GSG-AS700 : Gas steam-generator ANFRA A.S. 488 kW | 700kg/hr | 12 bar

Automatic gas steam-generator, available heating power of 488 kW - The production capacity 700 kg of hot steam per hour. Water feed can be connected directly to the water mains (if water is enough soft, maximaly 5°dH) or to a water treatment and the water / condensate mixing buffer tank. Regulation of the working steam pressure is adjustable in range from 1 up to 11.76 bar. The steam generator fulfils the requirements of the PED Directive 97/23/EC for pressure equipment. Produced in EU Read more »

Automatic gas steam-generator, available heating power of 488 kW - The production capacity 700 kg of hot steam per hour. Water feed can be connected directly to the water mains (if water is enough soft, maximaly 5°dH) or to a water treatment and the water / condensate mixing buffer tank. Regulation of the working steam pressure is adjustable in range from 1 up to 11.76 bar. The steam generator fulfils the requirements of the PED Directive 97/23/EC for pressure equipment. Produced in EU Read more » - GSG-AS900 : Gas steam-generator ANFRA A.S. 627 kW | 900kg/hr | 12 bar

Automatic gas steam-generator, available heating power of 627 kW - The production capacity 900 kg of hot steam per hour. Water feed can be connected directly to the water mains (if water is enough soft, maximaly 5°dH) or to a water treatment and the water / condensate mixing buffer tank. Regulation of the working steam pressure is adjustable in range from 1 up to 11.76 bar. The steam generator fulfils the requirements of the PED Directive 97/23/EC for pressure equipment. Produced in EU Read more »

Automatic gas steam-generator, available heating power of 627 kW - The production capacity 900 kg of hot steam per hour. Water feed can be connected directly to the water mains (if water is enough soft, maximaly 5°dH) or to a water treatment and the water / condensate mixing buffer tank. Regulation of the working steam pressure is adjustable in range from 1 up to 11.76 bar. The steam generator fulfils the requirements of the PED Directive 97/23/EC for pressure equipment. Produced in EU Read more » - GSG-AS1000 : Gas steam-generator ANFRA A.S. 700 kW | 1000kg/hr | 12 bar

Automatic gas steam-generator, available heating power of 700 kW - The production capacity 1000 kg of hot steam per hour. Water feed can be connected directly to the water mains (if water is enough soft, maximaly 5°dH) or to a water treatment and the water / condensate mixing buffer tank. Regulation of the working steam pressure is adjustable in range from 1 up to 11.76 bar. The steam generator fulfils the requirements of the PED Directive 97/23/EC for pressure equipment. Produced in EU Read more »

Automatic gas steam-generator, available heating power of 700 kW - The production capacity 1000 kg of hot steam per hour. Water feed can be connected directly to the water mains (if water is enough soft, maximaly 5°dH) or to a water treatment and the water / condensate mixing buffer tank. Regulation of the working steam pressure is adjustable in range from 1 up to 11.76 bar. The steam generator fulfils the requirements of the PED Directive 97/23/EC for pressure equipment. Produced in EU Read more » - GSG-AS1200 : Gas steam-generator ANFRA A.S. 837 kW | 1200kg/hr | 12 bar

Automatic gas steam-generator, available heating power of 837 kW - The production capacity 1200 kg of hot steam per hour. Water feed can be connected directly to the water mains (if water is enough soft, maximaly 5°dH) or to a water treatment and the water / condensate mixing buffer tank. Regulation of the working steam pressure is adjustable in range from 1 up to 11.76 bar. The steam generator fulfils the requirements of the PED Directive 97/23/EC for pressure equipment. Produced in EU Read more »

Automatic gas steam-generator, available heating power of 837 kW - The production capacity 1200 kg of hot steam per hour. Water feed can be connected directly to the water mains (if water is enough soft, maximaly 5°dH) or to a water treatment and the water / condensate mixing buffer tank. Regulation of the working steam pressure is adjustable in range from 1 up to 11.76 bar. The steam generator fulfils the requirements of the PED Directive 97/23/EC for pressure equipment. Produced in EU Read more » - GSG-AS1500 : Gas steam-generator ANFRA A.S. 1046 kW | 1500kg/hr | 12 bar

Automatic gas steam-generator, available heating power of 1046 kW - The production capacity 1500 kg of hot steam per hour. Water feed can be connected directly to the water mains (if water is enough soft, maximaly 5°dH) or to a water treatment and the water / condensate mixing buffer tank. Regulation of the working steam pressure is adjustable in range from 1 up to 11.76 bar. The steam generator fulfils the requirements of the PED Directive 97/23/EC for pressure equipment. Produced in EU Read more »

Automatic gas steam-generator, available heating power of 1046 kW - The production capacity 1500 kg of hot steam per hour. Water feed can be connected directly to the water mains (if water is enough soft, maximaly 5°dH) or to a water treatment and the water / condensate mixing buffer tank. Regulation of the working steam pressure is adjustable in range from 1 up to 11.76 bar. The steam generator fulfils the requirements of the PED Directive 97/23/EC for pressure equipment. Produced in EU Read more » - GSG-AS2000 : Gas steam-generator ANFRA A.S. 1395 kW | 2000kg/hr | 12 bar

Automatic gas steam-generator, available heating power of 1395 kW - The production capacity 2000 kg of hot steam per hour. Water feed can be connected directly to the water mains (if water is enough soft, maximaly 5°dH) or to a water treatment and the water / condensate mixing buffer tank. Regulation of the working steam pressure is adjustable in range from 1 up to 11.76 bar. The steam generator fulfils the requirements of the PED Directive 97/23/EC for pressure equipment. Produced in EU Read more »

Automatic gas steam-generator, available heating power of 1395 kW - The production capacity 2000 kg of hot steam per hour. Water feed can be connected directly to the water mains (if water is enough soft, maximaly 5°dH) or to a water treatment and the water / condensate mixing buffer tank. Regulation of the working steam pressure is adjustable in range from 1 up to 11.76 bar. The steam generator fulfils the requirements of the PED Directive 97/23/EC for pressure equipment. Produced in EU Read more »