Why can be Czech beer produced only in original Czech breweries?

Czech beer is world renowned brand. Why is it so unique, and why is it not produced elsewhere? Answer:Czech raw materials, specific manufacturing process and original technology of Czech breweries.

The Czech Republic – mainly known as Prague and beer

When a foreigner gets asked what is the first idea if they hear the Czech Republic, the most common answer is Prague … and Czech beer. The larger half of the planet´s residents are unaware that there is any Czech Republic. But telling just one word “Prague” helps orients themself very quickly … and they quickly add the word “beer“. As vodka belongs to Russia, whiskey to Scotland, wine to France, the Czech Republic is recognized by word beer.

Confirmed – Czech beer is the best in the world

- The best beer of the planet in the year 2013,by the prestigious British competition World Beer Awards is the Czech beer Primator. Beer won not only in its category, but also over other nearly 600 beers that were tasted blind by an international jury.

Czech beer is just one of the reasons why the Czech Republic and Prague in particular target destination for thousands of visitors from around the world. Why is the Czech beer so unique?

What is the specific of Czech beer?

History of Czech beer is tied to Pilsner and to a work of Bavarian brewmaster Josef Groll

Let’s go a little bit to the history. In 1842, brewed in Pilsen Bavarian brewer Josef Groll bottom-fermented beer brewed by recipe which he knew from home “Vilshofensk” brewery. Thanks to the manufacturing process, but also because of different raw materials that were available in the Czech Republic, the result was the result of excellent beer flavor and golden color, whose fame soon exceeded the boundaries of the city and later the Czech countries. The beer was so different from all kinds of beers, known in Europe at that time, that it became a name Pilsner (or Pils) a synonym for all light bottom-fermented beers. Although many tried to copy sensory properties of typical Czech beer and attempted to try it in hundreds of breweries around the world, never anyone except Czech breweries succeded in production of a drink that would be identical to the beer produced by Czech brewers from Czech hops and Moravian malt. And even Josef Groll himself failed when he tried to do it in Bavaria after he inherited his father’s brewery. Bright bottom-fermented beer that is still in the Pilsen brewery sold under the name Pilsner Urquell, became a model for all Czech breweries using Czech and Moravian beer raw materials and the 170 year old original recipe produced and still produces a drink that is as Czech beer known worldwide and is a typical product of the Czech nation.

Let’s go a little bit to the history. In 1842, brewed in Pilsen Bavarian brewer Josef Groll bottom-fermented beer brewed by recipe which he knew from home “Vilshofensk” brewery. Thanks to the manufacturing process, but also because of different raw materials that were available in the Czech Republic, the result was the result of excellent beer flavor and golden color, whose fame soon exceeded the boundaries of the city and later the Czech countries. The beer was so different from all kinds of beers, known in Europe at that time, that it became a name Pilsner (or Pils) a synonym for all light bottom-fermented beers. Although many tried to copy sensory properties of typical Czech beer and attempted to try it in hundreds of breweries around the world, never anyone except Czech breweries succeded in production of a drink that would be identical to the beer produced by Czech brewers from Czech hops and Moravian malt. And even Josef Groll himself failed when he tried to do it in Bavaria after he inherited his father’s brewery. Bright bottom-fermented beer that is still in the Pilsen brewery sold under the name Pilsner Urquell, became a model for all Czech breweries using Czech and Moravian beer raw materials and the 170 year old original recipe produced and still produces a drink that is as Czech beer known worldwide and is a typical product of the Czech nation.

Czech raw materials – Czech hops, Moravian malt, soft water, scientific cultivation of yeast strains

The cornerstone of Czech beer are raw materials for its production. Although all of what the Czech beer is produced, ie water, malt, hops and brewer’s yeast, is available in many countries around the world, but not enough for making beer that tastes identical with the drink produced in the Czech Republic. This specific properties of materials are currently tied with the Czech environment. Hundreds of years of selective breeding of cereals and hops, a unique strain of brewer’s yeast, soil composition, climate, water chemistry, but also a way of growing, harvesting and preparation of raw materials, all have a major impact on elsewhere inimitable characteristics of a typical Czech beer, a pale lager Pilsner type.

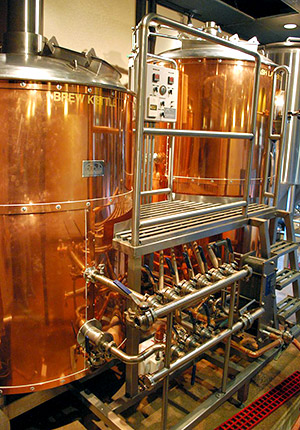

The unique technology of Czech breweries

In addition to the raw materials, the technology has a significant effect to the final sensory properties of beer (color, taste, zest, foaming, clarity, smell).This can be divided into manufacturing equipment (brewery) and the technological process of beer production.

The specifics of the technological process of Czech beer

Light lager, that is considered to be typical Czech beer, is brewed by decoction from two mashes of Moravian pale malt, soft water and Czech hops. Decoction method of brewing means that first part of wort (a solution of water and grist) is divided into two parts, with one part (the mash) is gradually brought to boiling and is then mixed with the rest of the production. During decoction method of brewing, the same is performed again, even at higher formature temperature. Mass is then strained through a straining sieve, received extract from crushed malt (the malted grains) becomes wort. This is heated together with hops, thereby the beer gaines its characteristic bitterness and aroma, and the wort is sterilized as well. At the end of the hops boiling is no longer blank is called wort, this is emptied when the hops swirling in a whirlpool tub. The wort is then cooled to fermentation temperature, oxygenated and leaves the brewhouse.  Beer is then reviled to fermenting room where shallow open fermentation tanks proceed lower main fermentation activity for yeasts Saccharomyces uvarum , a period is usually 6 to 12 days at temperatures of 6 – 12 °C. During the main fermentation the beer goes through several phases, which are manifested in the appearance and color of foam on the surface of the fermenting beer. This foam (so-called a quilt) must be collected during the last stage ot the beer fermentation so that it could not fall into the beer, which would result in degradation of the taste of beer called parasite bitterness. Incompletely fermentated beer is subsequently freed from yeast and pumped into the lager tanks, wherein at 1-3 °C matures, while extending the remaining yeast fermentation beer and carbonated waste product of fermentation carbonation. This beer gets a characteristic zest and fullness. Beer maturation takes place several weeks to months (stronger beer matures longer) after completion of the maturation, the beer is twisted into the bright beer tanks, adapted for pressure up to 3 bars. For bottling the beer must be get rid of residual yeast, either by filtration or by filtration and subsequent pasteurisation, thereby stabilizing the beer. Fermentation process is stopped by removing live yeast by filtration and killing the remaining yeast by pasteurization.

Beer is then reviled to fermenting room where shallow open fermentation tanks proceed lower main fermentation activity for yeasts Saccharomyces uvarum , a period is usually 6 to 12 days at temperatures of 6 – 12 °C. During the main fermentation the beer goes through several phases, which are manifested in the appearance and color of foam on the surface of the fermenting beer. This foam (so-called a quilt) must be collected during the last stage ot the beer fermentation so that it could not fall into the beer, which would result in degradation of the taste of beer called parasite bitterness. Incompletely fermentated beer is subsequently freed from yeast and pumped into the lager tanks, wherein at 1-3 °C matures, while extending the remaining yeast fermentation beer and carbonated waste product of fermentation carbonation. This beer gets a characteristic zest and fullness. Beer maturation takes place several weeks to months (stronger beer matures longer) after completion of the maturation, the beer is twisted into the bright beer tanks, adapted for pressure up to 3 bars. For bottling the beer must be get rid of residual yeast, either by filtration or by filtration and subsequent pasteurisation, thereby stabilizing the beer. Fermentation process is stopped by removing live yeast by filtration and killing the remaining yeast by pasteurization.

The specifics of the production technology of the Czech brewery

From the above procedure it is evident that the manufacturing process of Czech beer is quite complex, and in some respects quite different from the process of producing the majority of beers, which are manufactured elsewhere. One of the main reasons why Czech beer differs from other beers is the fact that while the world beer production process changed over time, in the Czech Repulic, the procedure is still the same – in many Czech breweries and microbreweries for already 170 years the beer has been produced strictly according to the original recipe by brewer Josef Groll. In order to observe the manufacturing process the construction of the brewery is very important.

Manufacturers who design the brewery follow a certain technological scheme that is optimized for the process of production of favorite beer in a given country. Here it must be said that every manufacturer has a little bit different contruction of the brewery, which also modifies in details from order to order. It is virtually impossible to find two same breweries in the world, which would include completely identical production technology. In most of the world’s breweries over the last 170 years manufacturing technology has been constantly evolved and modernized.

From small cosmetic changes of individual elements, to a fundamental change in the technological parts of the brewery. One of the major changes is the replacement of open fermentation in open fermentation vats by fermentation in closed, pressurized cylindrical-conical tanks. Introduction of technology HGB (which is nothing else than production of various strength of beers by diluting strong beer with water), beer stabilization with temperature pasteurization or replacing classical lautering through established malt grist with lauter filters and membranes.

From small cosmetic changes of individual elements, to a fundamental change in the technological parts of the brewery. One of the major changes is the replacement of open fermentation in open fermentation vats by fermentation in closed, pressurized cylindrical-conical tanks. Introduction of technology HGB (which is nothing else than production of various strength of beers by diluting strong beer with water), beer stabilization with temperature pasteurization or replacing classical lautering through established malt grist with lauter filters and membranes.

Many breweries have moved from demanding decoction method of beer wort production to a simpler, more energy and less time-consuming infusion methods for the preparation of the wort. All these and many other changes in production technology are called modernization of the brewery, which sounds very progressive, but in reality these steps follow one main goal. This is unfortunately not the taste of quality beer and consumer satisfaction, but the economic savings in production or reconstruction of the brewery and also cost savings in the production process of beer. Unfortunately, many of these modernization steps (and we can say that it si true for most of the changes) lead to degradation of the sensory properties of the resulting drink. While consumers over time get used to the changed taste of beer, economic savings for the manufacturer remain and bring them profit.

Brewers seldom realize that this trend gradually helps to lose their customers and future profits.

Consumers one by one over time are moving to another beverage or to better beers from other brands. Customer accustomed to be ripped off once they try the beer made according to the traditional recipe and they will change the brand of their favorite beverage from one day to another. Only when the beer producer realizes that fact, they will look for a way to bring traditional taste of beer. Unfortunately, without additional investment it is not usually possible because many modern breweries are not designed for the traditional method of brewing and to make better beer with this technology is virtually impossible.

Some Czech breweries (or almost all) have an advantage over most of the world’s breweries. As a result of the war, and 40 years of socialist property dozens of breweries were conserved in the form as they had been before the World War II. Centrally controlled state did not have competition at the brewing market and therefore invested in extensive modernization only to few large breweries, where most brewers insisted on keeping the traditional ways of brewing, although it seemed economically less advantageous.

Paradoxically, because of that in the Czech lands the tradition was kept despite the constant economic pressures on major modernization of breweries. Large breweries expanded and modernized in terms of automation of their own manufacturing process, however, it was interfered minimally. After the political changes in 1989 smaller breweries sleeping for long years of dilapidated buildings went also gradually into life where the new owners understood the value of the retained original equipment instead of cheaper substitutes for modern brewing technology, they started investing in intensive reconstruction with an emphasis on traditional production practices and technologies. Therefore, in a number of Czech breweries you can meet reconstructed equipment remembering times of Austria-Hungary or the First Republic. Production is of course already largely automated, but the manufacturing process of a typical Czech beer is strictly adhered.

Although the production of Czech beer in the traditional way is more difficult and more expensive than efficient production, implementation of current advanced technology is economically worthwhile anyway. Thanks to the great taste and low sales prices the Czech beer is a national drink. The per capita consumption in the Czech Republic is the highest in the world. Almost every Czech village has at least one pub and in the cities the beer is offered as a main drink in hundreds of pubs and restaurants. Czech beer production is also a good export product, and famous attraction for thousands of tourists who are comming to visit the country. Lower profit on one liter is offset by a large volume of drinks sold.

What differentiates the typical Czech brewery from most breweries of foreign production?

Characteristic features of the real Czech brewery or microbrewery mainly include the following:

- Brewhouse design allows decoction method of mashing by boiling in two to three mashes. In practice, this means the interconnection of mashing boilers and vessels for storing the rest of the wort that will allow pumping of mash and wort in both directions.

- Technology and design of the heating of brewhouse must allow the temperature rise of the wort between 0.5 to 1 ° C per minute. The heated solution shall no exceed the target temperature due not regulated hysteresis. Heating of wort must be uniform using the greatest heat transfer surface othervise it may lead to local caking of solids at the bottom of the brewing vessel.

- The design of the lauter tun and wort collectors (which is at microbreweries usually integrated into multifunctional brewing boiler) allows the first phase of gravity lautering of wort through a lautering cake, resulting from suspended solid particles of the wort (a solution of water and malt grist). In the second stage it must allow the sugaring with hot water.

- During the entire process of lautering, continuing according to the type of beer produced 1.5 to 4 hours, the temperature of wort in the first vessel and the wort in the second vessel can not fall below a predetermined temperature limit. For this both vessels must be equipped with either a high-quality insulation, or mild reheating of both vessels must be ensured.

- After the hops boiling is necessary to ensure separation of the spent hops grain from the wort in the whirlpool.

- Cooling system for wort with plate heat exchanger must ensure cooling of the entire volume of wort in a whirlpool tub in 60 minutes to the fermentation temperature of about 6 ° C and the oxygenation with the sterilized compressed air.

- The main fermentation of beer must run fundamentally in open fermentation vats or in non-pressurized cylidrical-conical tanks (overpressure 0 bar), with individual temperature control in each fermentation vessel.

- If fermentation of more types of beer takes place in the fermentation room at the same time using more than one strain of brewer’s yeast, it is necessary to ensure separation of fermentation vessels into separate rooms, to prevent the possibility of cross-contamination by different strains of brewer’s yeast.

- Construction of fermentation vessels and their location must allow collection of quilts of the dead yeast from the surface of the fermenting wort and cleaning without the risk of contamination other fermentation vessels by dirt, washing and sanitizing solutions.

- The construction of maturation lager tanks must allow their perfect automatic cleaning and sanitization, including periodic inspection of the container interior and safe manual mechanical cleaning.

- All elements of the brewery, coming into contact with the beer, its intermediate products and sanitation solutions must necessarily be made of high-alloy stainless steel for food industry.

- All welds must be made by certified welding materials, dedicated exclusively for the food industry, in a protective atmosphere of argon.

- Manufacturing, machining and assembly of stainless steel parts of the brewery (ie practically the entire brewery) must be carried out in the production area, which must not be machined and assembled with products made from other materials than just food stainless steel. This prevents contamination of the weld microparticles derived from processing such as conventional steel, which, over time, resulted in the formation of corrosive deposits in welds.

Cheaply made brewery does not bring expected profit for the owner

It is evident that the production of Czech type beer is a subject to a number of technological and design requirements, which a large part of foreign produced breweries to various degrees does not meet.

In particular, breweries and microbreweries produced in Asia, almost as a rule, they are made of poor quality stainless steel with a low doping level, the welds are contaminated by steel and other dust, components of the brewery are not meeting high requirements for resistance to sanitizing solutions. The result is that very early (after 1 year of operation) the formation of corrosive deposits especially at the welding parts, but also inside the vessels and pipeline routes appears and significantly degrade the properties of beer.

Brewery, in which corrosion occurs on inner surfaces, is practically useless and the only reasonable solution is to shut down the brewery and buy a new one. For comparison – life of Czech made brewery manufactured from high-quality food steel of European origin and well-made welds is up to 50 years.

A very common offense of cheap brewery producers is also poor workmanship of brewing components, whether they are components made by the manufacturer of the brewery, or parts purchased from cheap suppliers. It has become almost a rule that the customer who bought the brewery from cheap Asian manufacturer has a number of things “to finish at home” before starting the brewery or during its operation. This concerns particular the mutual connection of pipeline routes, gearboxes, pumps that leak.

Unfortunately we are meeting also cases where the brewer of the Asian brewery had to rebuild an essential part of the structure of the brewhouse completely, because it was not possible to brew Czech beer – although Asian manufacturer has guaranteed that the brewhouse is suitable for decoction brewing method, it was possible to brew only by an infusion process. Moreover, due to the poor design of heating in the brewhouse the wort is not heated up evenly, resulting in fusing of malt on one hand and on the other hand, insufficient heat gradient and thus a very long brewing cycle of one batch of beer.

For customers whose sole criteria for selecting the brewery suppliers is low cost, the choice is extremely cheap manufacturer with the possibility of a number of unpleasant surprises, unexpected additional costs and restrictions. Instead of the planned continuous production of beer the owner faces constant engineering hours when during operating downtime they must pay workers, incur additional costs for service, repairs and design modifications, while their credit of a reliable supplier of beer decreases. Solving problems with remote manufacturer is either time-consuming or even impossible. Such a company leads to a loss of customer confidence, steady decline in demand and ultimately often to the economic collapse of the entire business plan.

Even well-made brewery does not guarantee the production of Czech beer

Problems with the production of Czech beer type by far do not occur only at the breweries from Asia. As already mentioned, the development of brewing technology in most countries in the last century has led to significant changes of the technological process and equipment in breweries. As a result of this development, today most manufacturers in the world produce breweries very differently from Czech producers who have been trying to keep the traditional concept of the brewery for 170 years.

Problems with the production of Czech beer type by far do not occur only at the breweries from Asia. As already mentioned, the development of brewing technology in most countries in the last century has led to significant changes of the technological process and equipment in breweries. As a result of this development, today most manufacturers in the world produce breweries very differently from Czech producers who have been trying to keep the traditional concept of the brewery for 170 years.

A customer who buys a high quality brewery made by reputable manufacturers from Western Europe, equipped with a modern infusion brewhouse, can produce very good top-fermented beer, but not Czech bottom-fermented lager. The design of the brewhouse, number of elements, inability to collect quilt of the dead yeast and choise of closed fermentation tanks will not allow them to do it.

Then how to brew the Czech type of beer?

A customer who is interested in the actual production of Czech beer type, should study a very detailed information about the technology and design of the acquired brewery. Obviously, there are many conditions which the brewery must meet to make possible to produce traditional Czech beer. No random selection of Czech brewery manufacturer does not guarantee you that the brewery will meet all prerequisites for the production of Czech Premium Lager. Price pressure from customers often leads Czech manufacturer to various trade-offs, which in turn have the effect of restricting the operator in their manufacturing.

Satisfaction of the brewery operator starts from the dialogue with the producer

The company Mobilní pivovary s.r.o., as a manufacturer of traditional Czech breweries, fundamentally begins each session with a customer by a deep analysis of the customer’s ideas about the planned production assortment of beer. Only on the basis of this dialogue we will suggest to the customer a technological and design solutions of the brewery or microbrewery that allows them the production of the desired types of beers without compromise.

The most popular brewery in the world is with technology for Czech beer type brewing

The most common order of customers from abroad is currently the delivery of the technology, enabling the production of traditional Czech pale lager – Pilsner type. For these customers, we design and produce breweries structurally designed so that, regardless of the geographic location, they are able to produce the same beer taste characteristics, such as, for example, they had the opportunity to taste in pubs in Prague. Dozens of such Czech breweries and microbreweries are already operating in many countries.

If the customer is interested in making other kinds of beer, we can equip the brewery with technologies capable of producing practically all the world’s known beer beverages. We supply the breweries very often with open fermentation vats or with the cylindrical-conical tanks. Our restaurant microbreweries BREWORX and container microbreweries MOBBEER can produce beer without compromise by decoction or infusion method.

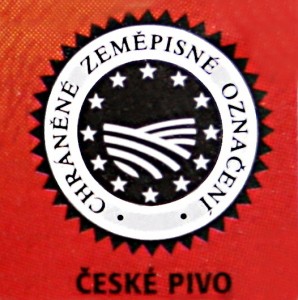

Czech beer as a trademark

Numerous foreign breweries attempt to copy the taste of Czech beer, riding on its reputation as well as the efforts of many Czech breweries to produce under the name of Czech beer every sort of drink, with deviating taste, composition, method of production, raw materials and other properties from traditional recipes, and that have led to the registration of name “Czech beer” as a trade mark, protected by legislation of the European Union.

Czech beer is protected geographical indication of the European Union, which aims to preserve the good name of Czech beer and geographical quality of beer produced in the Czech Republic.

Protected geographical indication (PGI) Czech beer was registered in Council Regulation (EC) no. 1014/2008, on the entry of certain names in the register of protected designations of origin and protected geographical indications (České pivo (PGI), Cebreiro (PDO)).

The aim of the registry is to protect the tradition of Czech brewing, production technology, quality beer and prevent the occurrence of imitation, which would abuse the good name of Czech beer and its unique properties. Furthermore, the point is not to mark as a Czech beer products produced in the Czech Republic by non-traditional methods or produced by traditional methods, but abroad.

Characteristics of beer, which may wear a trademark the Czech beer, provides specifications published in the Official Journal of the EU 2008/C-16/05. There it is registered how such a technological processes arises. Further specified raw materials that must be used for the production of beer, such as barley malt, hops, water of appropriate quality, and type of yeast capable for the technology of so-called bottom fermentation. A part of the specification is also geographical characteristics of the place where it is possible to produce Czech beer.